Product Characteristics

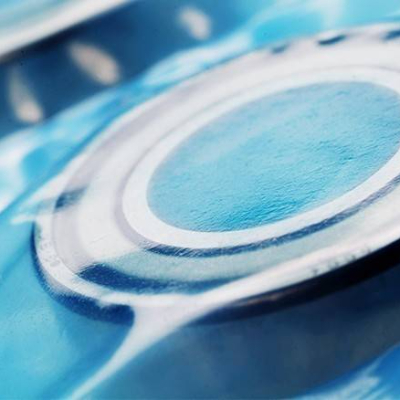

BRANOfol M3 are blue dyed, special polyethylene film with double-sided active VCI corrosion protection which effectively protect metal parts from corrosion during transport or storage.

They are water-proof, weldable and suitable for automatic packaging as well as bag production. BRANOfol M3 are available from 40 to 300 μm and also available as VCI-embossing film.

BRANOfol products continuously release small amounts of corrosion protection agents (VCI: Volatile Corrosion Inhibitors), helping to provide effective protection against corrosion for metal parts during transport or storage.

The protecting atmosphere is, depending on the volume of the package, available after a short time. This holds true even after having opened the package for a short time – the protecting atmosphere will be rebuilt immediately afterwards.

Duration of Protection

Depending on climate conditions and how well the packaging is sealed, BRANOfol M3 can offer protection for up to twelve months. The duration of protection can be adapted when the precise application is known.

BRANOfol M3(nitrite free)

Protects steel,cast iron(only on contact), zinc plated steel, tin, aluminum, chromium, zinc, copper and its alloys reliably against corrosion.

※ For further questions about metals and alloys, our technical support will assist you.

Advantages

· Environmentally friendly corrosion protection without oiling and greasing

· Packaging material and corrosion protection in one

· Metal parts are ready for use immediatly

· Time efficent packaging process

· Easy to dispose and recyclable

· Protects against humidity

· Non-hazardous material

· High elasticity and tear strength

· Development of customized solutions possible

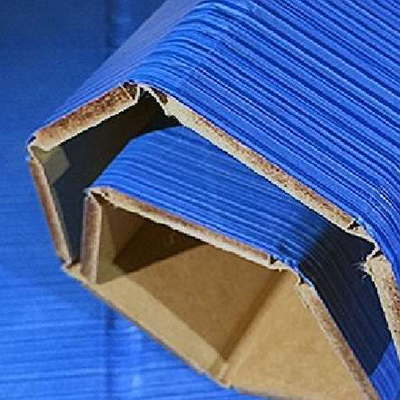

Delivery forms

Flat film, sheets, bags, half tubes, hoods, tubes, side-pleaded Tubes, pallet liners, Boxed hoods, elastic string bags, zip lock bags.

Storage

Cool and dry, protected from direct sunlight. Shelf-life in the original packaging up to three years.

Disposal

BRANOfol M3 can be recycled. Soiled film has to be disposed through waste incineration.

Operation safety

BRANOfol M3 corresponds to TRGS 615. Please see for further information the safety information sheet.

Types

M3 - standard

M3 S - shrinkable

M3 XS - highly tearproof

M3 SXS - highly tearproof and shrinkable

M3 XA - violet and antistatic

M3 ESD - black and electrically conductive

M3 FL - flame retardant

M3 KL - cross-laminated

M3 UV - UV-stable

M3 XE - extra elastic

M3 SUV - shrinkable and UV-stable

Facts

| Parameter | Test method | Unit | BRANOfol |

Tensile strength lengthwise/transversely | DIN EN ISO 527- 3/2/500 | MPa | > 25 |

Stretching lengthwise/transversely | DIN EN ISO 527- 3/2/500 | % | > 600 |

| Dart-Drop | ASTM D1709/A | g | > 550 |

| Water vapour permeability | DIN EN ISO 15106 (23 °C, 85 % r. F.) | g/m2 * d | ≤ 1 |

| Operating temperature | Temporary: max. 70 ° Constantly: -10 °C bis 40 °C | ||

| The mechanic parameters surpass the specifications of the norm DIN 55530. | |||

The information corresponds with typical values of BRANOfol M3.10XS Binding are the respective product specifications.

滬公網(wǎng)安備31011702005477號(hào)

滬公網(wǎng)安備31011702005477號(hào)