Product Characteristics

Mineral oil-based anticorrosion oil without solvent, wax, wool fat, silicone or inorganic ash-building additives.

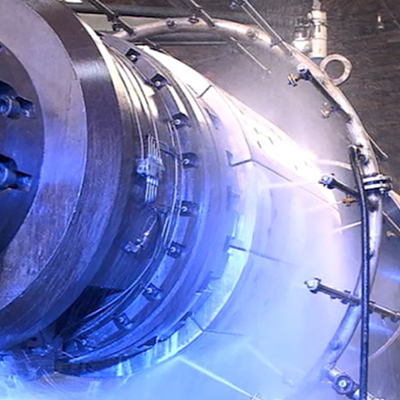

BRANOrol 32/10 protects in two different ways:

- As oil film, directly on metal surfaces (protective coating)

- Through giving off small amount of active anticorrosion ingredients above oil level in the surrounding atmosphere: the VCI principle (Volatile Corrosion Inhibitor). A permanent protecting atmosphere is built up in an enclosed cavity.

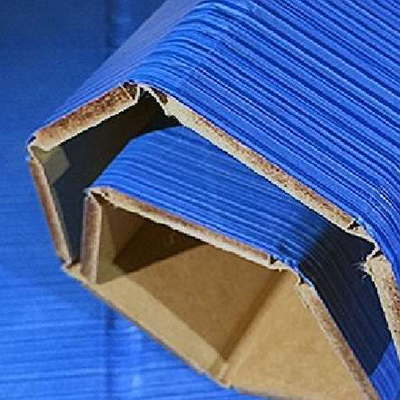

Application

For cavity protection of gears, pumps, engines, cylinders, pipes, tanks, during shipment and storage of newly manufactured units; even during seasonal closure (farm machines, snow remover and boats). Not for cavity of car bodies.

BRANOrol 32/10 is simply poured or sprayed into the cavity for protection.

Afterwards all openings are sealed as tightly as possible.

Range of Protection

Especially made for the protection of iron. If copper, brass or bronze is present, BRANOrol has to be fully sprayed on it at the beginning of the preservation. If magnesium, cadmium, zinc or lead is present, a certain rate of material abrasion is expected.

Dosage

In general, up to 1 m3: 300 ml BRANOrol 32/10 per m3 of cavity. ( Please inquire about bigger units)

BRANOrol 32/10 is to be used as described above (packaging/ protection of certain kinds of metal pieces). Otherwise, no responsibility for caused damages can be taken.

Technical Details

| Density at + 20 °C: | 0.91±0.01g/cm3 |

| Flash Point: | > 200 °C |

| Neutralisation number: | about 15 |

| Kinetic viscosity at + 40°C: | 42-47 mm2/s |

This is for the standard type of BRANOrol 32/10. Other viscosity on request.

Durability

Receptacles Steel drums(200l) plastic jerri-cans | original locked unlimited 24 months | after advent 12 months 6 months |

Depreservation

Before pouring in the operating oil, the amount of BRANOrol 32/10 should be removed by pouring out. The cleaning of metal surfaces covered with BRANOrol 32/10 is possible with all usual cleaning and degreasing processes.

Compatibility

Compatibility test is recommended for varnishes and plastics. Rubber: different kinds of rubbers, which are resistant to mineral oil, such as engine oil, gear oil and hydraulic oil, are also resistant to BRANOrol 32/10. The swelling caused by BRANOrol 32/10 might be slightly stronger.

Other operating fluids: can be mixed with mineral oilbased lubricating oil and operating oil ( important while draining BRANOrol 32/10 and to fill it up with operating fluids afterwards. It is advisable not to add any BRANOrol 32/10 additives to operating oil because their specification values might change.) Not or only partially mixable with synthetic oil. Not mixable with non-flammable hydraulic oil (glycol-water mixture).

Delivery Forms

Containers of 15 litres

Storage

Do not store in blazing sun; always keep containers closed.

Operation Safety

Please see for further information the safety data sheet.

Disposal

All instructions regarding correct disposal are listed in the safety data sheet.

The information given is in line with current state of knowledge.

It is non-binding and might have to be adjusted to meet local requirements. No liability is accepted for this information. Please contact us in case of doubt.

滬公網(wǎng)安備31011702005477號

滬公網(wǎng)安備31011702005477號