Fast and Optimal Void Fill, Seamless Integration

Ergonomic Automatic cut mechanism and an EDS mode

Time savings Fanfolded packs of paper offer minimal handling time

Cost efficient Runs at high speed allowing maximum box throughput

The ergonomical solution for filling boxes in high volume pack station environments

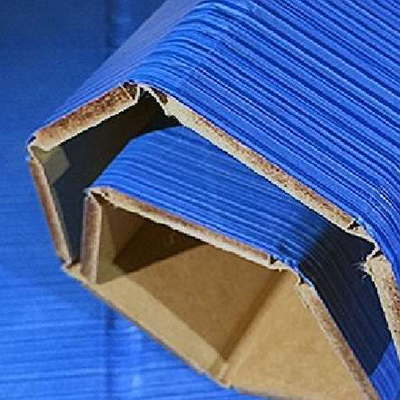

The converter forms single layer kraft paper into a high volume star-shaped paper configuration, which can be used as a very effective filling material.

It prevents products from shifting around in their box, ensuring damage-free arrival at the end destination. The converter has an automatic cut mechanism

which eliminates manual tearing and gives the operator more comfort.

Both high and low volume operations benefit from this ergonomical solution.

Go Green

Our company works with FSC certified suppliers. Paper is climate neutral, recyclable and also a renewable source.

Specifications of the system

| Converter | Paper |

| Dimensions: 43x45x46 cm | Base weight: 50 gr/m2, 70 gr/m2 |

| Weight: 10 kg | Pack length: 500 m, 360 m |

| Voltage: 100-230 Volt | Paper width: 38 cm |

| Power: 150 Watt | Average pack weight: 9.5 kg, 9.6 kg |

| Speed: 1.4 m/s | Average yield: 1.5 m3 |

| Cut method: automatic |

Our Added Value

Packaging Engineering

Ranpak analyses and reports on your current packaging solution. The drop test shows exactly how much shock is transmitted to your products through the packaging. Ranpak then suggests alternatives how to improve protection or save costs.

Integrated Applications

The Ranpak Added Value department can design structures, frames and other innovative solutions to integrate the packaging converter anywhere around, above or under a packing area.

Packaging Training

Training from our packaging experts will help your packers to use up to 20% less packing material, without compromising the quality of the packaging.

Successful in these industries

· Logistics · Lighting · E-commerce · Toys & Sport · Publishing

· Decoratives · Cosmetics · Computers · Pharmaceuticals · Gourmet food

滬公網(wǎng)安備31011702005477號

滬公網(wǎng)安備31011702005477號