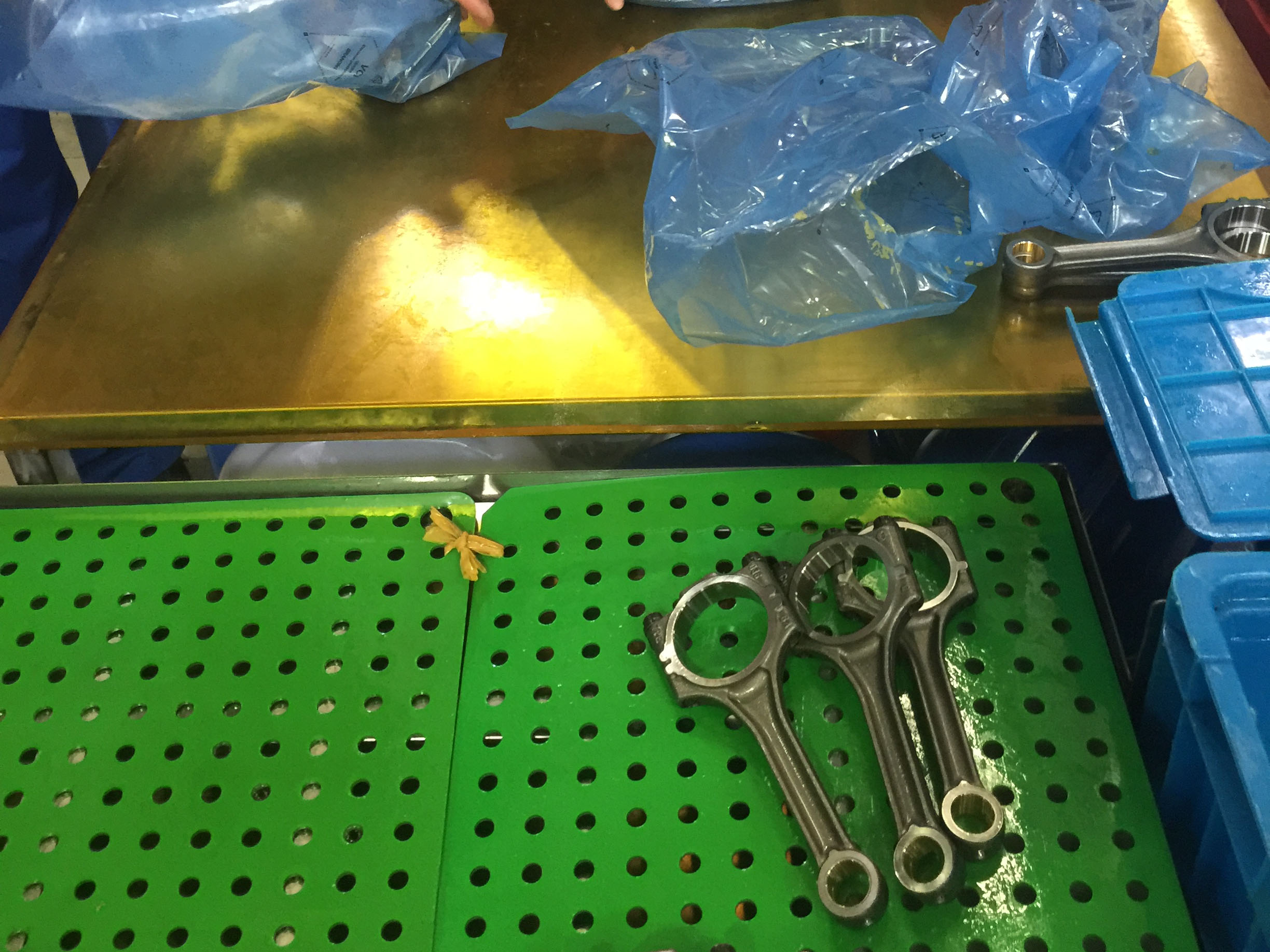

Freedom from corrosion, vapour phase rust prevention solutions for engine connecting rods

Connecting rod is an important part of the engine, used to connect the piston and crankshaft, can change the reciprocating motion of the piston into the rotary motion of the crankshaft, so it is subject to greater compression and tension forces. This requires connecting rods with high mechanical strength and toughness, connecting rods are mostly made of medium carbon steel, medium carbon alloy steel and other materials to meet the requirements.

There are 2 areas on the connecting rod that are prone to rust:

Threads and bolts on the large end.Threads rust because rust-causing aqueous machining fluids and cleaning agents are left behind during the tapping and cleaning process, and the bolts, which are attached to the threads after assembly, are similarly corroded as a result.

Hosiery.The holes at the small end of the connecting rods are inlaid with bronze bushings, mostly of wear-resistant phosphor bronze, which contains phosphorus causing easy discolouration and corrosion.

B+Z Rust protection film style specially tailored for connecting rods

Convenient for quick sealing and storage

B+Z for different rust protection periods

Recommended solutions for more cost-effective gas phase rust prevention

?

Rust prevention within 3 months

Gas phase antirust bag with the use of magnesium chloride desiccant, in the case of a well sealed bag, the desiccant will be fully absorbed inside the bag, antirust bag volatile gas on the surface of the connecting rod to form a protective layer of gas will be separated from oxygen and the connecting rod, to achieve the effect of rust prevention.

B+Z also recommends the use of A antirust oil, which is a thin, dry, solvent-volatile antirust oil that can be packaged in ordinary plastic bags to achieve rust prevention.

Desiccant and antirust film used in conjunction

Better rust prevention

?

Rust prevention period 3-6 months

Rustproof paper and magnesium chloride desiccant provide longer rust protection.Compared with antirust bag (film), antirust paper contains more gas-phase antirust components and releases antirust gas faster, which can make the package quickly filled with antirust gas and form more timely and effective antirust protection. In addition, the concentration of antirust gas in the antirust paper package is higher, which can form a thicker gas protective layer on the surface of the connecting rod, and the antirust effect is better.

The B+Z KU range of antirust papers offers enhanced rust protection for ferrous and non-ferrous metals, and is chip-resistant, flexible and unbreakable.

?

Rust prevention period more than 6 months

It is recommended to use a combination of antirust oil, antirust bag and magnesium chloride desiccant to prevent rust, and in the coastal belt where the air is humid and in the rainy season, antirust paper should also be used.

Rust protection varies depending on metal material, processing, cleaning and packaging, and B+Z rust protection solutions are tested in wet heat and actual storage environments before being packaged in bulk to minimise risk and provide a better price/performance ratio.

滬公網(wǎng)安備31011702005477號(hào)

滬公網(wǎng)安備31011702005477號(hào)